Globe Valves model

Globe valves are used for regulating flows inside of a pipeline. The desired degree of control or regulation, defines the type of valve and if it should be designed with or without cage guiding.

Where the flow conditions and the regulation requirements are not very severe, these valves are supplied without cage guiding, with flat or conical disc. It is important that the disc guiding be in the body or in the seat, in order to obtain trouble free operation without valve seizing and also a good seat tightness.

For applications that require regulation under severe conditions and where cavitations, flashing, etc… may occur, we design different type of discs, cages, seats… to guarantee that the valve will function trouble free and as required by the design conditions.

Our globe valves are typically constructed from cast iron, ductile iron, cast carbon steel, gun metal, stainless steel, alloy steels, and forged steels, under our customer requirements.

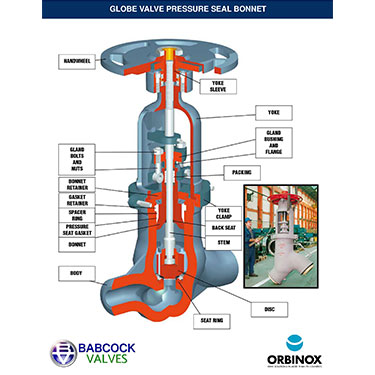

They are served in a wide range of different designs, that vary from bolted bonnet to pressure seal bonnet, that can be made with threaded in or welded seat.

Different baffle configurations (parabolic, flat…) can be supplied. “Y” pattern design, and angle for body are also available.

Design

ASME B16.34, BS 1573.

Testing

ASME B16.34, API 598, BS EN 12266-2, ISO 5208.

Sizes

1/2” to 48” (Bigger Size on Request)

ANSI Class

150LB to 2500LB

If you need more information and catalogs, please consult ORBINOX local office.