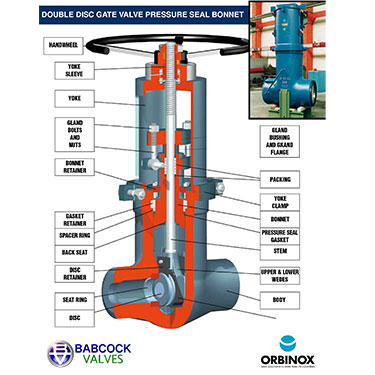

Double Disc Gate Valves model

The so called double disc valve incorporates a double disc, wedge and seat system which makes this design unique, being designed to assure a reliable operation under the most severe service conditions.

The two independent trunnion mounted discs which permit each disc to rotate a few degrees during closing. This rotating feature allows the discs to seat in a different position on each closing stroke which provides even wear and prevents small imperfections from growing into major leaks.

The double wedging assembly is designed to impart the stem thrust to each disc which provides bi-directional sealing at low or zero differential pressures. As the differential pressure across the valve increases, the seating load on the downstream disc increases to provide high differential pressure sealing while the upstream disc moves away from the upstream seat; and allows the valve to be used in applications with large thermal transients.

This valve is commonly used for isolation of boiler water main feed lines. It is also very useful for cryogenic applications, when the effect of the differential thermal contraction may require an extra thrust to close the valve properly (zero-leakage).

A wide range of construction materials, actuation systems and accessories are available for each case.

Design

ASME B16.34, API 600, BS 1414.

Testing

ASME B16.34, API 598, BS EN 12266-2.

Sizes

2” to 72” (Bigger Size on Request)

ANSI Class

150LB to 4500LB

If you need more information and catalogs, please consult ORBINOX local office.